Lye Calculation: Experience in Soapmaking

Practical Approaches to Lye Measurement

Soapmaking was once a craft passed down from generation to generation. Many soapmakers relied on traditional recipes and their own experience to determine the correct amount of lye. They knew the general ratios between fats (e.g., animal fat, olive oil) and lye (e.g., potash or caustic soda). However, calculating the exact proportions of ingredients was very challenging. There were several reasons for this.

The Importance of Experience: Tradition Over Science

Before modern chemistry, soap makers primarily relied on experience and tradition. Over generations, techniques and “rules” were passed down, based on trial and error. These rules were not scientifically precise, but they were sufficient to create usable soap.

In the earlier centuries, chemistry was not as advanced as it is today. The exact way in which fats and lye react (saponification) was known, but there was a lack of a clear, detailed scientific understanding of chemical reactions and specific ingredient ratios.

The theoretical foundation for the precise calculation of chemical reactions—known as stoichiometry—had not yet been developed. There were no established principles that would have allowed the creation of exact formulas for soap making. Instead, rough estimates were made.

There were no modern instruments for precisely measuring chemical substances (such as titration devices or modern scales). Simple scales were used, which only allowed rough measurements, and volumetric measurements (e.g., using bottles or cups) were also not always accurate.

Temperature played a role in saponification (e.g., in maintaining the right reaction temperature), but precise thermometers were either unavailable or expensive and inaccurate. The lack of precise temperature control meant that the saponification process depended on experience and estimates rather than exact calculations.

The exact composition of fats and lye could not be reliably measured. Chemical analysis of raw materials (fats, lye, water) was inaccurate, making it difficult to calculate the exact amount of lye required to completely saponify a specific amount of fat.

In traditional soapmaking, it was difficult to measure the excess lye. An excess of lye could lead to a harsh, unpleasantly alkaline soap that could harm the skin, but this could not be easily quantified without specialized methods like pH measurement or titration.

Soapmaking relied heavily on the “feel” of the soapmaker. Many processes, such as determining whether enough lye had been added to completely saponify the fat, depended on visual and tactile cues that were not exactly measurable.

The soapmakers not only had problems with the accuracy of the tools used, but also with the purity of the materials available.

Different fats (such as olive oil, beef tallow, or lard) have varying chemical compositions. This meant that the fat content and the types of fatty acids in each batch could differ. Without precise methods for determining the exact proportion of unsaturated or saturated fatty acids, it was impossible to make exact calculations.

Lye was often made from plant ash (e.g., oak wood or seaweed). The concentration of alkalis (potassium or sodium carbonate) in the ash could vary greatly. To test the quality of the lye, soapmakers would float it in water: the more lye was required, the heavier the solution was, and it would sink slowly.

Soapmaking could vary greatly depending on the type of soap being produced. For example, adding different oils, herbs, or other ingredients would yield different results. The desired consistency and hardness of the soap also played a role and could be adjusted by varying the amounts of lye and fat.

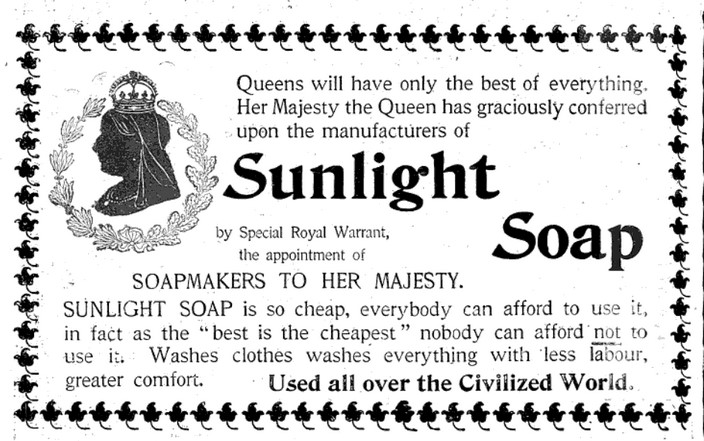

Although they had to work with imprecise testing methods, varying quality of materials and sometimes only orally handed down secret recipes, these soap makers produced great soaps. Normal soaps for the commoner, cleaning soaps, cheap soaps for the poor and toilet soaps for the elite of society.

The methods of the soap makers

As early as the 18th century, attempts were made to create tables for soap production. These tables indicated how much lye was needed for a specific amount of fat.

However, these tables were often based on empirical data, as chemical analysis was not very accurate at the time. Potash (potassium carbonate), which was commonly used, could have varying concentrations.

Although modern alkalimetry was developed only in the 19th century, soapmakers knew simple tests to check the strength of lye. For example, they would drop the lye onto their skin to estimate its strength (a risky and inaccurate method). Or they used organic pH indicators like litmus or red cabbage juice to roughly determine the pH.

Such tests helped assess the quality of the lye, especially since potash, made from burning plant ashes, was often uneven in strength.

Soapmakers observed the chemical reaction during the process (called saponification). They checked the consistency and behavior of the mixture. For example, if a layer of fat formed, it indicated that the lye was insufficient.

Before the advancement of modern chemistry, soapmaking was deeply rooted in experience and tradition. Techniques were passed down over generations, relying on trial and error rather than scientific precision. In earlier centuries, the lack of stoichiometric theory and precise measurement tools meant that soapmakers worked with rough estimates and empirical methods.

Raw materials, such as fats and lye, varied significantly in composition and quality, making exact calculations nearly impossible. Instead, soapmakers relied on practical knowledge and observational skills to control the saponification process. Tools for measuring temperature, lye strength, and ingredient ratios were either unavailable or highly imprecise, leading to inconsistent outcomes.

Despite these challenges, the intuitive methods and adjustments made by skilled soapmakers highlight the critical role of experience. Their ability to adapt to variations and rely on tactile, visual, and empirical tests ensured the production of usable soap, even without the scientific knowledge or advanced tools we have today. This underscores the enduring value of tradition and hands-on expertise in the absence of scientific precision.