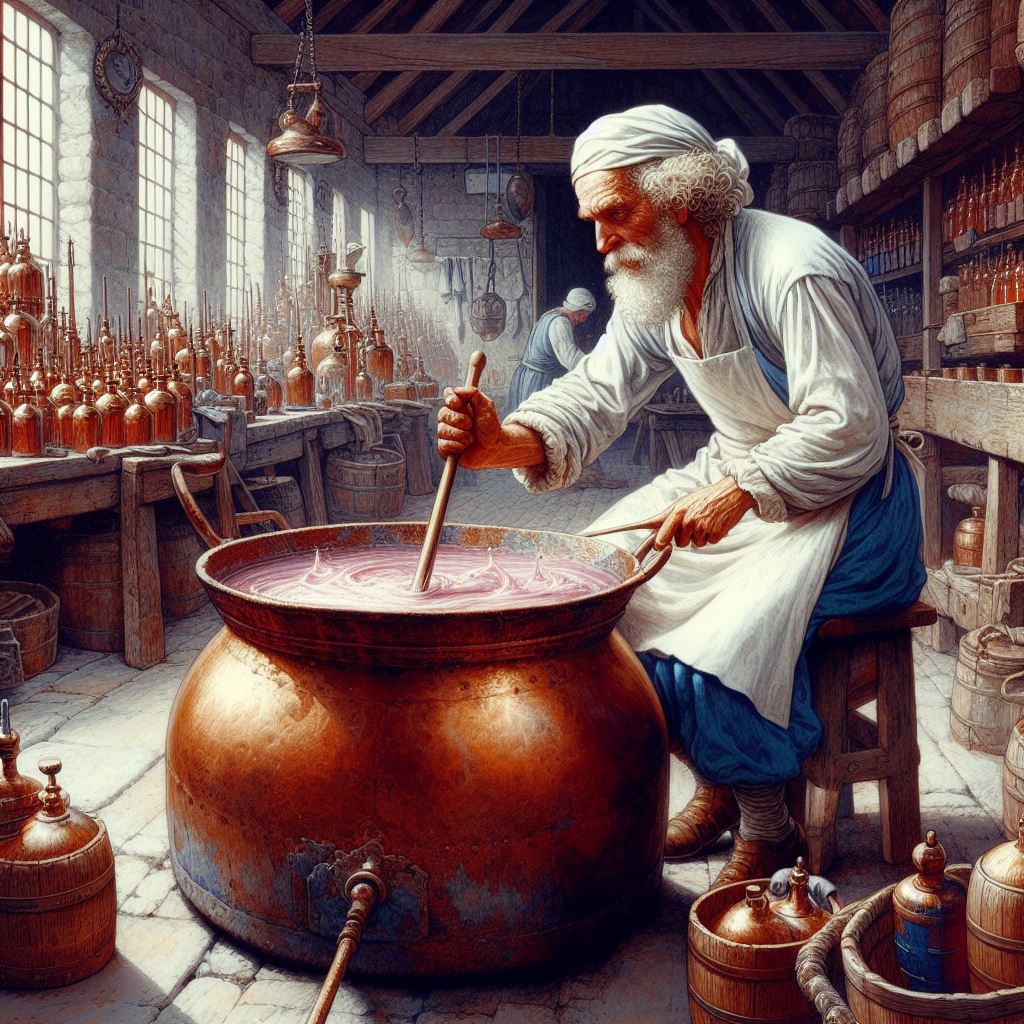

Hot Process soaping – generations ago!

Hot Process soaping – generations ago! Explore the intricacies of soap production, from cooking to hardening. Learn precise methods for creating scum-free, pure soap bars of exceptional quality. This method is derived from a 300-year-old book for master soap makers. Step 1 – Cooking: Mastering the Initial Phase of Soap Production Cook all oils in 400 liter lye with 8-10° Baumé on low temperature, stir occasionally. As soon as it starts to simmer decrease the heat. Cook for a few hours. Add fresh 150 – 200 liter lye with 15-18° Baumé and stir for 15 minutes Cook for a few hours (days!) till the soap has an homogeneous apperance. Add 150 liter fresh lye with 15-18° Baumé. After cooking for another 2 hours the “Vorsieden” pre-cooking is done. Step 2 – Making Curd Soap: Refining the Soap Separation Process Remove the pot from the heat. Add a salt solution with 20 – 25° Baumé and stirr. When enough salt solution is added the soap seperates from the salt water. After 5 or 6 hours remove the 2/3 of the salt water. It should have 15 – 16° Baumé. Step 3 – Clear Boiling (“Klarsieden”): Achieving Clarity and Purity Add 600 – 700 liter lye with 25° Baumé. Turn on the heat. The soap expands and is very foamy. Stir it. Permanent stirring is important in this phase to decrease the cooking time. After 3 or 4 hours of slowly cooking increase the heat. This step should be ready after 8-10 hours resting. You will see little corns in lye. If you squezze the corns between the fingers thin and hard sheds should be formed. Let it rest for another few hours. Remove the soap from the now very concentrated lye. Step 4 – First Melting: Purifying the Soap through Melting Process The melting process takes place to remove excess lye, salt and impurities. Add 400 liters fresh lye with 8-10° Baumé. Increase the temperature and stir constantly. Stop stirring when all soap is melted. Cook 5 – 8 hours. To prevent clumping up add now and then pure water or lye with 2° Baumé. The soap must be separate from the lye during the whole time. Proof this with a glass [sic!] of the liquid. The soap swims on top of the lye. Let the soap rest for at least 8 hours. Step 5 – Second Melting: Final Refinement for Pure, High-Quality Soap Pour 150 liter of a soda/water solution (4,5-5° Baumé) in another pot, heat it till it almost cooks. Put the soap in this pot. Keep it warm for 4-5 hour and stirr occasionally. You know if the soap is ready when the impurities are visible again. Let the soap rest for 20 – 24 hours. The impurities are now in the weaker lye beneath the layer with soap. Remove the foam and save it for later. When you reached the pure soap remove it carefully and put it in a container. You will recognize the pure soap on the yellow-golden colour and the liquidity. Don’t forget to pour the soap through a fine plastic sieve. The now washed soap should have now a bright yellow colour, “does not have too much lye (is not “zapping”). Step 6 – Hardening: Achieving Uniformity and Stability in Soap Texture Now you have a container with soap. Stir it while it cools down to get plain and uniform soap. If all steps were done the soaps should yield: Soap Scum: 70-80 kg Pure soap: 1050-1080 kg Dirty and lyeheavy soap: 250-300 kg To get an excellent and beautiful toilet soap, bleach the palmoil. .

Carbonate Soaps

Carbonate Soaps A common misinformation about soda soaps debunked! Misinformation about soda soaps is common, especially in the USA. Some people believe that soap made with only fats and washing or baking soda produces a good soap. However, this is not true as soap making was a well-guarded secret and only specialists were able to make great soaps. They learned the exact procedures which took weeks, used different temperatures, different alkali substances, salts, additives, and more. They also did not have measuring tools like a pH meter but had methods to test the pH and quality without them. Challenges in Early Soap Making While simple saponifying of fatty acids is the first step of soda soap making, it does not produce a good soap. Using rancid fat, bones, skins, corpses, and other waste materials was common among older generations. These soaps were good enough to remove stains from clothes and strip fats from the skin but were not suitable for hands, bodies, or even the face. In Europe, people did not have the idea to use self-made soaps for the skin, and most German and Austrian families bought their body soaps instead of making them. Innovation and Controversy in Soap Making The knowledge of soap making was lost over time and oceans, and even in WW2, Germans and Austrians could buy fine body soaps and curd soaps for cleaning. War soaps had zero superfat and glycerine but were not lye-heavy. In those days, clay was used to fill the soap and make it heavier, along with sodium silicate, talc, alumina, kaolin, and other materials. The use of these materials was considered cheating and sometimes even forbidden by law. Using the recipes from well-known companies, soda soaps can be superb, with a wonderful smell, nice lather, and a soft feeling on the skin. However, making such soap requires time, love, and lots of practice. Soap making is a difficult process and was not easy even 220 years ago. The effort put into making the soap is well worth it. Crafting Excellence: The Art and Challenge of Soda Soap Making Using the recipes from well-known companies, soda soaps can be superb, with a wonderful smell, nice lather, and a soft feeling on the skin. However, making such soap requires time, love, and lots of practice. Soap making is a difficult process and was not easy even 220 years ago. The effort put into making the soap is well worth it.

Soapmaking in the centuries

Soapmaking in the centuries Travel through time and discover the evolution of soap making! From skilled craftsmen using animal fats and herbs, to mechanized production and introduction of chemical compounds, see how soap making evolved to meet the demands of society. Learn about famous soap makers and the countries where they came from, and uncover the secrets behind the textures and fragrances of soap from different centuries. Don’t miss this journey through the history of soap making! Evolution from 1500 to 1900 It is difficult to find precise information on the methods and properties of soap making in each century, as the techniques and formulas varied over time. However, here is some information on soap making in different centuries: 15th century: Soap making in the 15th century was often a craft practiced by skilled soap makers. In Europe, animal fats such as lard and tallow were boiled with lye from wood ash or potash to make soap. Some soap makers also added herbs or flowers to give the soap scent and color. The specific properties of soap at this time are not known. 16th century: Soap making in the 16th century in Europe continued to evolve and improve. Animal fats and lye were still used, but plant oils such as olive oil and castor oil were also used. Soap was often cooked in large kettles and poured into molds to harden. Some soap makers also added fragrances and dyes. Soap at this time was often hard and had a rough texture. 17th century: In the 17th century in Europe, soap making continued to be refined. Soap made from soda instead of potash was introduced, resulting in a milder soap. Soap was also made from palm oil and coconut oil. Soap makers in France and England became particularly famous for their soaps, which were often enriched with fragrances and dyes. Soap at this time often had a smoother texture than in previous centuries. 18th century: In the 18th century, soap making techniques were further refined. Several new plant oils, such as linseed oil, were introduced to create a wider range of soaps. Soap making became more mechanized, resulting in higher production and a more consistent texture. Some soap makers also added salt to soap to increase its durability. Soap at this time was often softer and creamier than in previous centuries. 19th century: In the 19th century, further advances were made in soap making, particularly in the United States. Synthetic surfactants and other chemical compounds were introduced to create soaps with specific cleaning properties. Soap production became fully mechanized and automated, resulting in even higher production and a wider range of soaps. Soap at this time often had a smooth texture and was more effective at cleaning than in previous centuries. In conclusion, the journey through the evolution of soap making techniques and properties from the 15th to the 19th century offers a fascinating glimpse into the ingenuity and innovation of human craftsmanship. From the humble beginnings of skilled artisans utilizing animal fats and herbs to the industrial revolution that mechanized production and introduced chemical compounds, the story of soap making is one of adaptation and progress. As we reflect on the advancements made over the centuries, we are reminded of the intricate interplay between tradition and innovation, shaping the textures, fragrances, and efficacy of soap throughout history. Join us in celebrating the legacy of soap makers past and present, and continue to explore the rich tapestry of human creativity in the realm of cleanliness and hygiene.

SOAPING HISTORY

Soaping History Here you’ll find all blog posts about the history of soapmaking. AllgemeinHistoryTutorial Ancient soap recipes Read More HPTutorial Hot Process soaping – generations ago! Read More ChemistryHistory Carbonate Soaps Read More AllgemeinHistory Soapmaking in the centuries Read More

SOAPING TUTORIALS

Soaping tutorials Here you will find all tutorials about soap making. AllgemeinHistoryTutorial Ancient soap recipes HPTutorial Hot Process soaping – generations ago!

SOAPING CHEMISTRY

Soaping Chemistry Here you will find all blog posts about the chemistry of soap making. AllgemeinChemistrySoap-er Knowledge Glass Disease AllgemeinChemistrySoap-er Knowledge Understanding Lyes, Alkaline Substances, and NaOH ChemistryHistory Carbonate Soaps