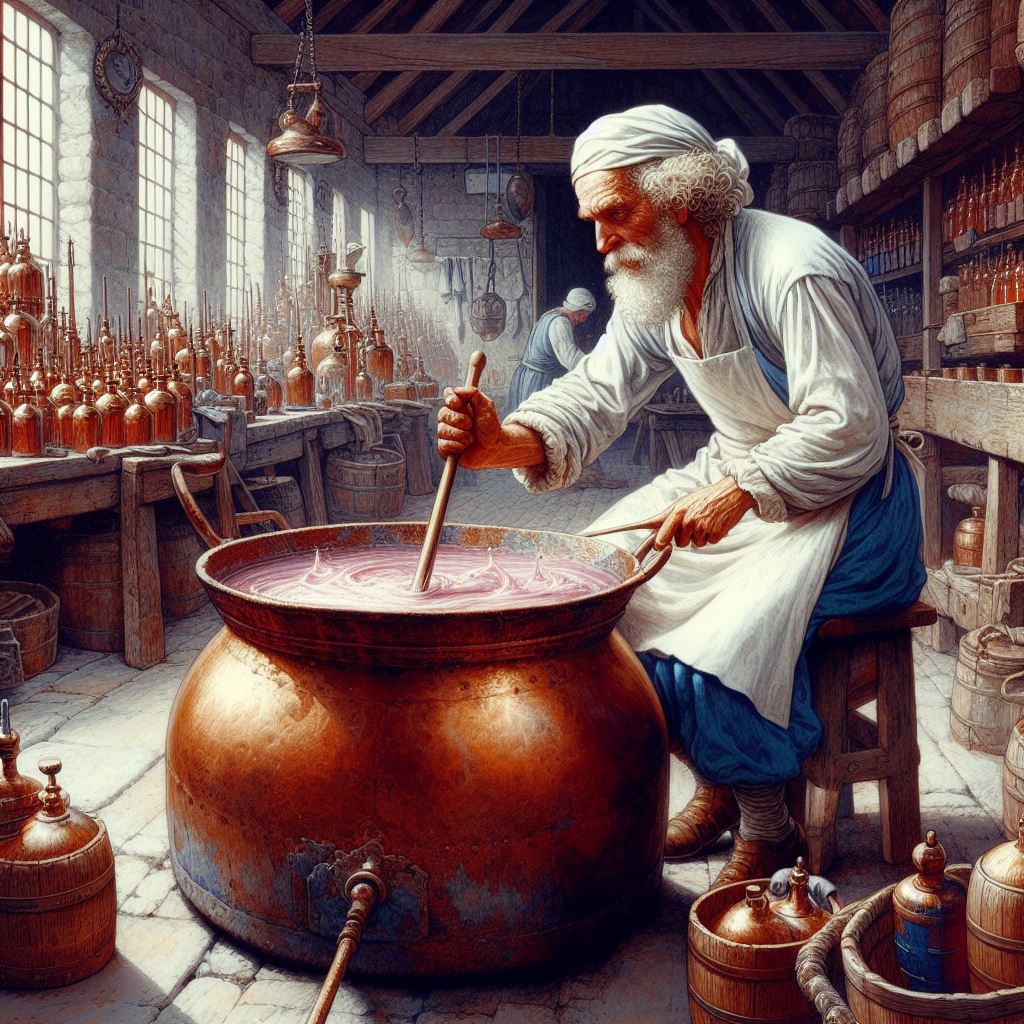

Hot Process soaping – generations ago!

Hot Process soaping – generations ago! Explore the intricacies of soap production, from cooking to hardening. Learn precise methods for creating scum-free, pure soap bars of exceptional quality. This method is derived from a 300-year-old book for master soap makers. Step 1 – Cooking: Mastering the Initial Phase of Soap Production Cook all oils in 400 liter lye with 8-10° Baumé on low temperature, stir occasionally. As soon as it starts to simmer decrease the heat. Cook for a few hours. Add fresh 150 – 200 liter lye with 15-18° Baumé and stir for 15 minutes Cook for a few hours (days!) till the soap has an homogeneous apperance. Add 150 liter fresh lye with 15-18° Baumé. After cooking for another 2 hours the “Vorsieden” pre-cooking is done. Step 2 – Making Curd Soap: Refining the Soap Separation Process Remove the pot from the heat. Add a salt solution with 20 – 25° Baumé and stirr. When enough salt solution is added the soap seperates from the salt water. After 5 or 6 hours remove the 2/3 of the salt water. It should have 15 – 16° Baumé. Step 3 – Clear Boiling (“Klarsieden”): Achieving Clarity and Purity Add 600 – 700 liter lye with 25° Baumé. Turn on the heat. The soap expands and is very foamy. Stir it. Permanent stirring is important in this phase to decrease the cooking time. After 3 or 4 hours of slowly cooking increase the heat. This step should be ready after 8-10 hours resting. You will see little corns in lye. If you squezze the corns between the fingers thin and hard sheds should be formed. Let it rest for another few hours. Remove the soap from the now very concentrated lye. Step 4 – First Melting: Purifying the Soap through Melting Process The melting process takes place to remove excess lye, salt and impurities. Add 400 liters fresh lye with 8-10° Baumé. Increase the temperature and stir constantly. Stop stirring when all soap is melted. Cook 5 – 8 hours. To prevent clumping up add now and then pure water or lye with 2° Baumé. The soap must be separate from the lye during the whole time. Proof this with a glass [sic!] of the liquid. The soap swims on top of the lye. Let the soap rest for at least 8 hours. Step 5 – Second Melting: Final Refinement for Pure, High-Quality Soap Pour 150 liter of a soda/water solution (4,5-5° Baumé) in another pot, heat it till it almost cooks. Put the soap in this pot. Keep it warm for 4-5 hour and stirr occasionally. You know if the soap is ready when the impurities are visible again. Let the soap rest for 20 – 24 hours. The impurities are now in the weaker lye beneath the layer with soap. Remove the foam and save it for later. When you reached the pure soap remove it carefully and put it in a container. You will recognize the pure soap on the yellow-golden colour and the liquidity. Don’t forget to pour the soap through a fine plastic sieve. The now washed soap should have now a bright yellow colour, “does not have too much lye (is not “zapping”). Step 6 – Hardening: Achieving Uniformity and Stability in Soap Texture Now you have a container with soap. Stir it while it cools down to get plain and uniform soap. If all steps were done the soaps should yield: Soap Scum: 70-80 kg Pure soap: 1050-1080 kg Dirty and lyeheavy soap: 250-300 kg To get an excellent and beautiful toilet soap, bleach the palmoil. .