Soda ash – what, why and how?

Soda ash – what, why and how? In this article, I would like to provide you with a more detailed explanation of soda ash on soap. Soda ash is a white layer that can form on the surface of handmade soap and is composed of sodium carbonate, which is generated during the saponification of oils and fats. What is Soda Ash? Soda ash is a chemical compound with the formula Na2CO3. It is a white, inorganic powder found in nature in the form of minerals such as a mixture of sodium carbonate and sodium hydrogen carbonate (trona) or sodium bicarbonate (sodium hydrogen carbonate). Soda ash is also commonly referred to as washing soda or soda. How Does Soda Ash Form on Soap? Soda ash is produced during the saponification of oils and fats using a lye solution, which can be either sodium hydroxide or potassium hydroxide. During saponification, the fatty acids in the oils and fats react with the lye to create salts of fatty acids, which constitute the actual soap. In addition to soap, the saponification process also yields sodium carbonate. Sodium carbonate is a byproduct of saponification, formed when the lye solution within the soap mixture reacts with carbon dioxide. Carbon dioxide is a gas present in the air and may also originate from the water used in the soap-making process. Additional Insights: Effect on Fragrance: In some cases, soda ash formation might trap fragrance oils, affecting the scent of the soap. Soap makers may need to consider this when formulating their recipes and choosing curing methods. Humidity Impact: Humidity levels in the curing environment can influence soda ash formation. Higher humidity can accelerate the formation of soda ash, while lower humidity may slow it down. Soap makers may need to adjust their curing conditions accordingly. Alternative Prevention Methods: Besides the methods mentioned, some soap makers also use techniques like spraying the soap surface with rubbing alcohol after pouring it into molds. This can create a barrier that helps prevent soda ash formation. Long-Term Storage: Even if soda ash forms initially, it may sometimes dissipate over time during the curing process or with proper storage. Soap makers often recommend allowing the soap to cure for several weeks to months for optimal quality, during which soda ash may naturally diminish. How Can Soda Ash on Soap Be Prevented? Soda ash can be prevented through several measures: Carefully cover the soap mixture: Always securely cover the soap mixture with plastic wrap or a cloth to prevent it from coming into contact with carbon dioxide. Allow the soap to fully cure Do not unmold the soap too early: before removing it from the mold, typically around 24 hours. Use distilled water: Distilled water does not contain carbon dioxide. Using distilled water can reduce the formation of soda ash. Use distilled water: Distilled water does not contain carbon dioxide. Using distilled water can reduce the formation of soda ash. How Can Soda Ash on Soap Be Removed? Soda ash can be removed from soap using a steamer or a damp cloth. Steamer: Place the soap in a steamer and steam it for a few minutes. This will dissolve the soda ash, making it possible to wipe it away with a soft cloth. Damp Cloth: Rub the soap with a damp cloth to dissolve the soda ash, then wipe it away with a soft cloth. Click Here for additional information about soda ash! Soda Ash Additional Information Soda ash is a naturally occurring substance found in minerals in nature. Soda ash is used in various industries, including glassmaking, detergent production, and papermaking. Soda ash can also be used as a cleaning agent. Edit Template Conclusion Soda ash is not harmful to the skin but can affect the appearance of the soap. To avoid soda ash formation, follow the above-mentioned tips.

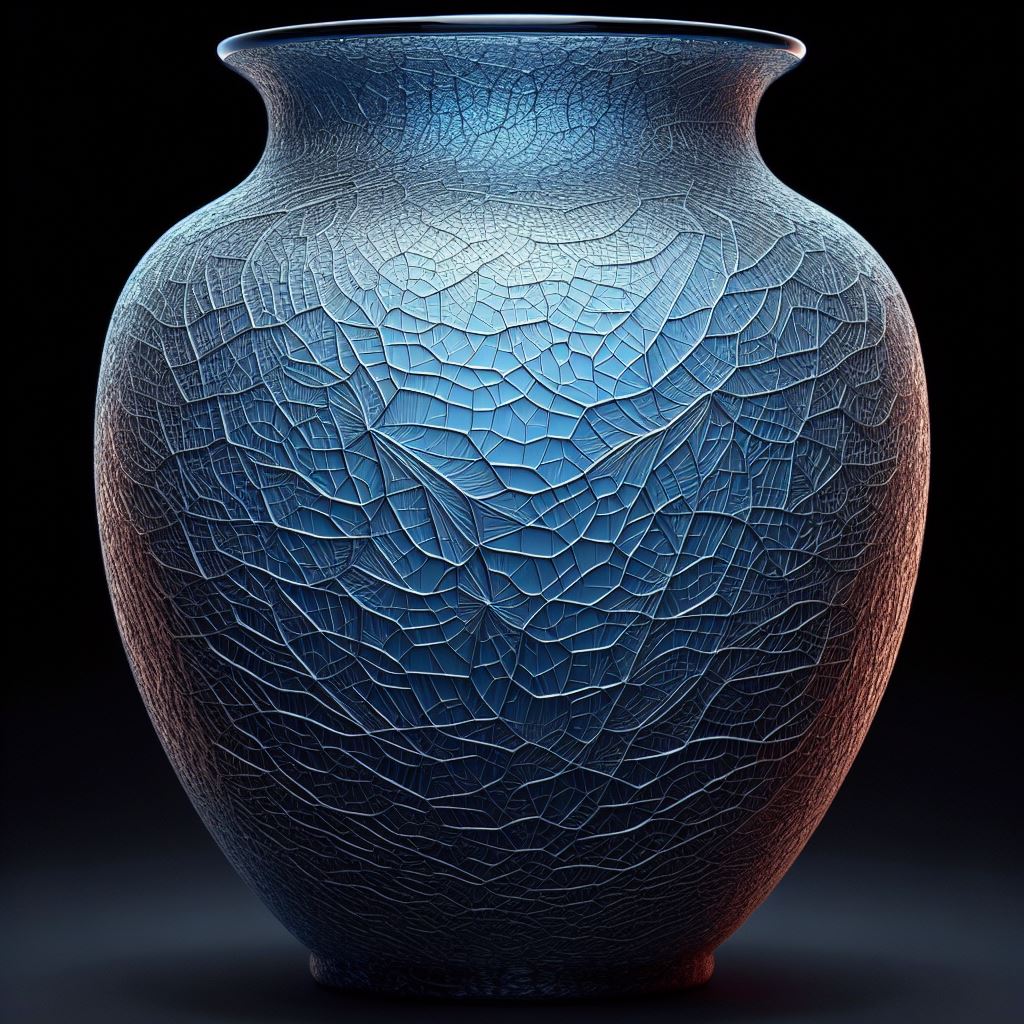

Glass Disease

Glass Disease: A Threat to Glass Products Discover the unseen menace lurking within your glass products. From weeping to fragmentation, learn how Glass Disease wreaks havoc and why your glass containers may be part of the problem. Stay tuned for insights into prevention and detection. Protect your glass investments before it’s too late. Glass Disease, also known as “glass malady” or “glass sickness,” is a serious issue that can compromise the integrity of glass products such as windows and doors. This process of decomposition can lead to a variety of symptoms, including weeping, crizzling, spalling, cracking, and even fragmentation. Understanding the causes, symptoms, and prevention measures of this disease is crucial for ensuring the longevity of glass products. Causes of Glass Disease Causes of Glass Disease The main cause of Glass Disease lies in the unstable chemical composition of the glass formula. This instability can be caused by various factors, including: Alkali leaching: Alkali metal ions can leach out of the glass, leading to an increase in the pH level on the surface and the dissolution of silicon in the glass. Lime and alkali metals: The ratio of lime to alkali metals in the glass plays a crucial role in its stability. A lack of lime oxide can cause the alkalis in the glass to become insoluble. Temperature and humidity: Changes in temperature and humidity can affect the composition of the glass, thus endangering its stability and integrity. Environmental conditions: External factors such as humidity and temperature can accelerate the process of glass decomposition. Symptoms of Glass Disease Symptoms of Glass Disease Recognizing the symptoms of Glass Disease is important to take timely action. These include: Weeping: Leakage of alkalis from the glass, known as “weeping.” Crizzling: Formation of a characteristic network of fine cracks visible to the naked eye. Spalling: Formation of distinct cracks on the surface of the glass, accompanied by material detachment. Cracking: Formation of distinct cracks on the surface of the glass. Fragmentation: Breakdown of the glass object into pieces in the final stage of the disease. Why Glass Containers Should Be Avoided Glass containers should be avoided in soap making as the lye used in soap making can react with glass. Lye is highly alkaline and can attack the surface of the glass, leading to the release of alkalis. This exacerbates the process of alkali leaching, thus accelerating the development of Glass Disease. Prevention and Detection Glass Disease poses a serious threat to the integrity of glass products and requires a fundamental understanding of its causes, symptoms, and prevention measures. Through regular inspections, proper care, and control of environmental conditions, we can contribute to prolonging the lifespan of glass products and maintaining their beauty and functionality. In soap making, it is especially important to avoid glass containers to prevent accelerating Glass Disease, as lye can react with glass. Conclusion: In conclusion, Glass Disease presents a significant challenge to the longevity and integrity of glass products. From the insidious onset of weeping to the dramatic fragmentation in its final stages, this degradation process demands attention and action. Understanding its causes, symptoms, and preventive measures is crucial for preserving the beauty and functionality of glass items. Whether it’s through controlling environmental conditions, avoiding reactive materials like glass in certain processes such as soap making, or regular maintenance, proactive steps can mitigate the impact of Glass Disease. Let’s safeguard our glass investments and ensure they stand the test of time against this silent adversary.

Understanding Lyes, Alkaline Substances, and NaOH

Understanding Lyes, Alkaline Substances, and NaOH Discover the powerful world of lyes and alkaline substances! From their chemical properties to real-world applications like cleaning and manufacturing, learn how these compounds shape our industries while navigating their potential hazards. Get ready to dive deep into the chemistry behind NaOH and its role in our daily lives! Lye: A lye is an aqueous solution of a hydroxide. Lyes are alkaline, meaning they have a pH value > 7. Lyes can decompose organic materials and may cause burns. Examples of lyes include sodium hydroxide (NaOH), potassium hydroxide (KOH), and calcium hydroxide (Ca(OH)2). Alkaline Substances: Alkaline substances are bases that, when dissolved in water, release hydroxide ions (OH-). Lyes are a subset of alkaline substances. Not all alkaline substances are lyes, for example, sodium bicarbonate (NaHCO3). Alkaline substances have the following properties: They have a pH value > 7. They neutralize acids. They saponify fats into soap. NaOH: NaOH is the chemical formula for sodium hydroxide. Sodium hydroxide is a white crystalline substance. It is strongly alkaline and breaks down in water to form caustic soda. Sodium hydroxide is used in various industries, such as in the chemical industry, in the food industry, in paper production, and in cleaning. In summary: Lyes are aqueous solutions of hydroxides. Alkaline substances are bases that release OH- when dissolved in water. Lyes are a subset of alkaline substances. NaOH is the chemical formula for sodium hydroxide, a strongly alkaline substance that decomposes in water to form caustic soda. Important: Lyes and alkaline substances can be hazardous. When handling them, wearing protective gloves and goggles is advisable. In case of contact with lyes or alkaline substances, rinse the affected area immediately with water.